The ability of a small piece of material to exert an invisible force over distance is nothing short of fascinating. Magnets, the silent workhorses of modern technology, are indispensable components in everything from motors and hard drives to medical imaging devices and speakers. But have you ever wondered how these essential materials are actually made? Manufacturing magnets is a precise, multi-step process that transforms raw materials into components capable of creating a powerful, lasting magnetic field.

1. The Raw Materials: What Makes a Magnet?

The first and most critical step is selecting the right materials. The properties of the final magnet—its strength, temperature resistance, and resistance to demagnetization—are determined by its composition.

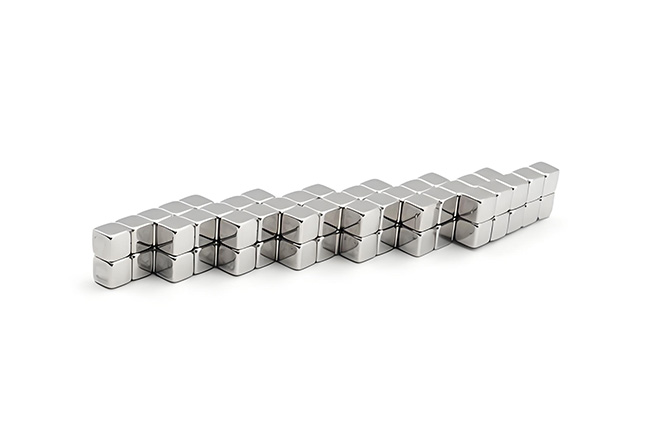

Neodymium Iron Boron (NdFeB): This is the material for the world's strongest permanent magnets, often referred to as "super magnets." Key ingredients include neodymium, iron, and boron.

Ferrite (Ceramic): Composed mainly of iron oxide and barium or strontium carbonate. These are less powerful but inexpensive and highly resistant to corrosion.

Alnico: An alloy of aluminum, nickel, and cobalt, known for its high residual magnetization and excellent temperature stability.

Samarium Cobalt (SmCo): A high-performance rare-earth magnet, second only to NdFeB in strength, prized for its exceptional resistance to heat and demagnetization.

2. Manufacturing Processes: Shaping the Magnet

There are several methods used to shape and form the magnetic material, each optimized for a different type of magnet.

A. Powder Metallurgy (Sintering)

This is the most common method for making high-performance rare-earth magnets like NdFeB and SmCo.

1. Milling: The raw materials are first melted together and cast into an ingot. This ingot is then crushed and ground into a fine powder.

2. Pressing: The magnetic powder is placed into a die and pressed into the desired shape. During this pressing stage, a magnetic field is applied to align the particles in a preferred direction. This crucial step is called orientation and dictates the direction of the final magnetic field.

3. Sintering: The pressed part (the "green compact") is heated in a controlled atmosphere (like a vacuum or inert gas) to a temperature below its melting point. This process fuses the particles together, creating a dense, solid magnet.

4. Machining: The sintered blocks are hard and brittle, so they must be cut, ground, and shaped using specialized diamond tools to meet final dimensional tolerances.

B. Casting

This method is primarily used for Alnico magnets.

1. Melting and Pouring: The constituent metals (Al, Ni, Co, and Fe) are melted in an induction furnace and poured into molds.

2. Heat Treatment: The cast parts undergo a specific heat treatment cycle, often in the presence of a magnetic field, to develop their optimal magnetic properties. The presence of the field during cooling is what makes these powerful magnets.

C. Binding and Injection Molding

For producing magnets with complex shapes, or when high precision is required without machining, powders can be mixed with a polymer binder.

1. Compression Bonding: The magnetic powder is mixed with a plastic binder (like epoxy) and pressed into a mold. These magnets are isotropic (can be magnetized in any direction) and offer high dimensional accuracy.

2. Injection Molding: The magnetic powder is compounded with a thermoplastic polymer. This mixture is then heated and injected into a mold, similar to plastic component manufacturing. This allows for extremely intricate shapes and is often used for small components in sensors or motors.

3. Magnetization: Bringing the Magnet to Life

After the material has been shaped, it is still an unmagnetized piece of metal—it is a magnetic material, but not yet a magnet. The final, most dramatic step is magnetization.

The Process: The finished magnet part is placed inside a coil or fixture connected to a powerful magnetizing machine. A brief, high-current pulse (a burst of energy) is sent through the coil.

The Result: This pulse generates an intense, external magnetic field that forces the microscopic magnetic domains within the material to align permanently. Once aligned, the material becomes a permanent magnet.

4. Finishing and Testing

The final steps ensure the magnet is durable and meets specifications.

Coating: Many types of magnets, especially NdFeB, are susceptible to corrosion. They are typically coated with a protective layer, such as nickel-copper-nickel (Ni-Cu-Ni), zinc, epoxy, or sometimes gold, to prevent degradation.

Testing: Every batch is tested to confirm its magnetic performance. Instruments like a Gauss meter measure the surface field strength, while a hysteresis graph is used to check key magnetic properties like residual induction (Br), coercive force (Hc), and maximum energy product ((BH)max).

The Enduring Appeal of the Magnet

The manufacturing process for magnets is a marvel of precision engineering, chemistry, and physics. From the careful blending of rare-earth elements to the final, powerful jolt of current that gives them their magnetic field, these tiny components are critical to nearly every aspect of modern life, quietly powering the technology we rely on every day.

We will contact you within 24 hours. ( WhatsApp/facebook:+86 15957855637)